First-of-a-kind robotic recycling and manufacturing solutions

Fairmat integrates the latest technology to recycle carbon composites, transforming the reclaimed carbon composite into innovative products.

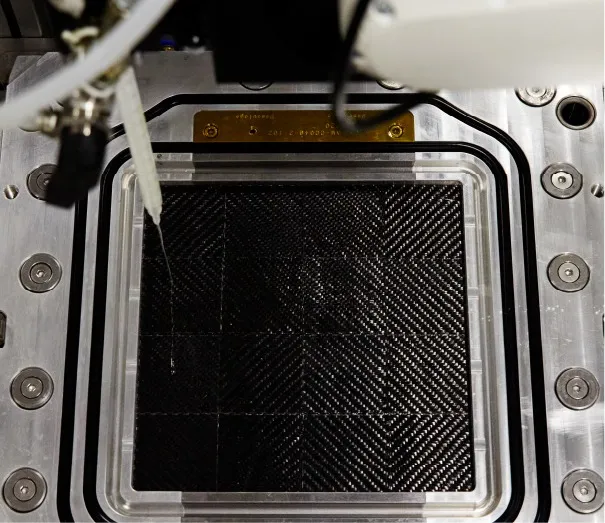

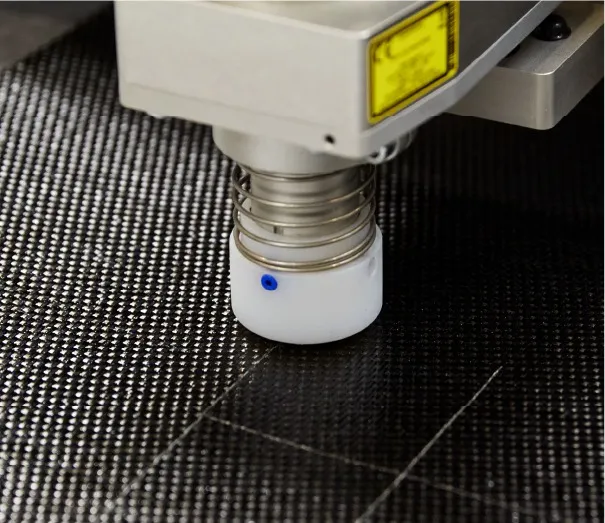

Robotic Cutting Recycling

Our factory in France is home to the first Robotic Recycling that utilizes the latest technology to recycle carbon composites. This innovative system mechanically transforms reclaimed carbon composites into a new high-tech carbon composite made entirely from 100% recycled content, the Chip.

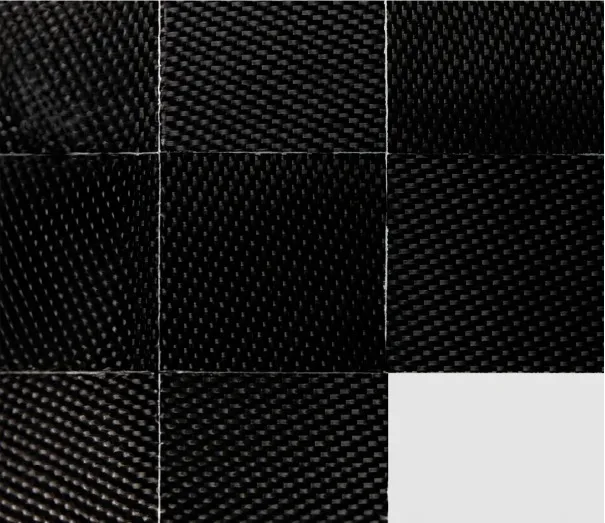

From Waste to Chip

At Fairmat, we built a closed-loop system that prevents carbon composites from ending up in landfills, recycling waste into a high-performance advanced recycled material, the Fairmat Chip.

Reclaimed Waste

Collect and sort CFRP scraps and end-of-life products

Recycled Composites

Mechanically cut waste into UD and BD Chips

Repurposed Chips

Conduct testing to analyze chip properties

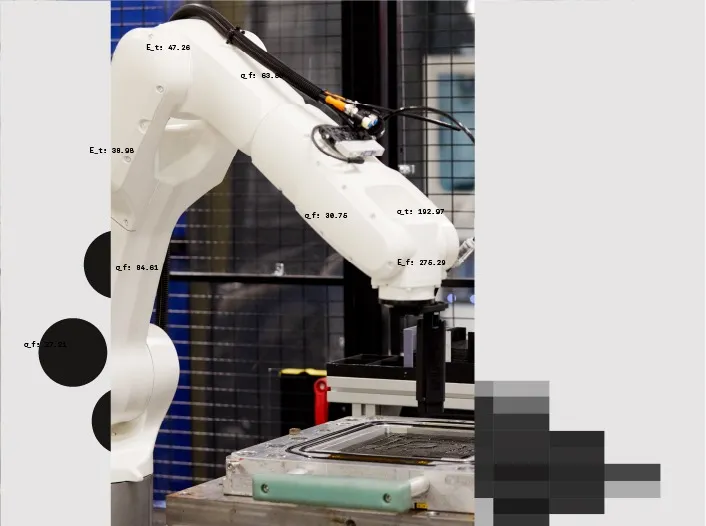

Pick and Place Manufacturing

Once transformed, the chips are seamlessly integrated into our manufacturing process. Robots expertly pick the chips from cartridges and place them into various structures, producing standard laminates and semi-finished parts and products.

Our Technological Edge

Our processes are powered by several proprietary, interconnected tech pillars, including:

Material Science Innovation

Autonomous Systems

AI Integration

Advanced Factory Software

Data Loops

These components are assembled using an industrial infrastructure approach that relies on cloud computing and APIs, ensuring a process that is both flexible and scalable.

Robotic-designed layouts are at the core of our technology

The four elements of a perfect layout