At Fairmat, quality is our top priority

Our rigorous quality control processes ensure that every step of production is monitored from reclamation to final inspection

Tech-driven solutions for a circular tomorrow

Quality Control Steps

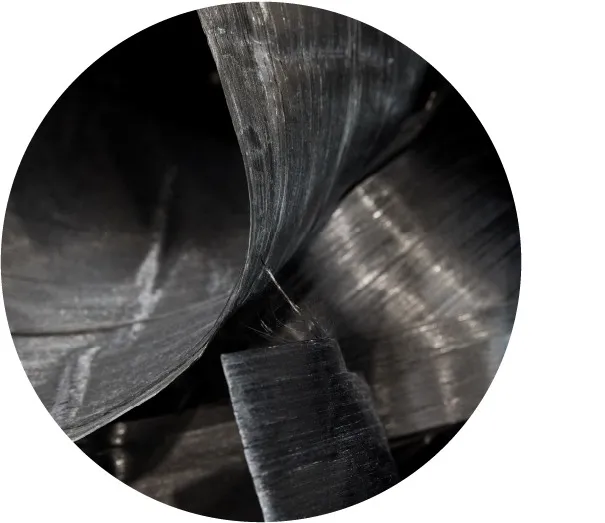

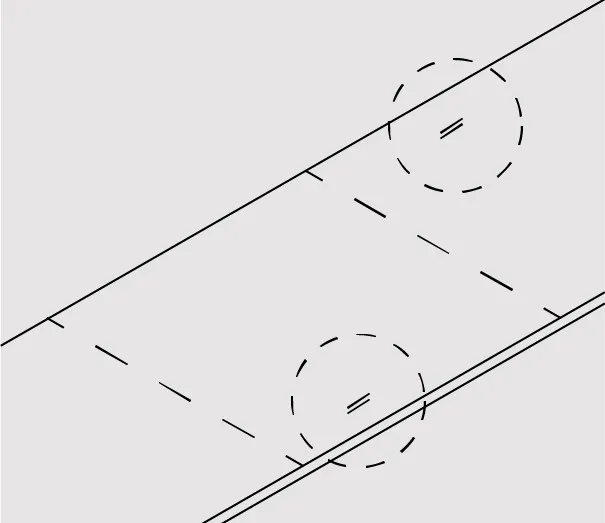

1. Reclamation

Every batch of reclaimed CFRP waste is carefully documented and experimentally characterized using an array of mechanical and physico-chemical measurements to determine its suitability for recycling.

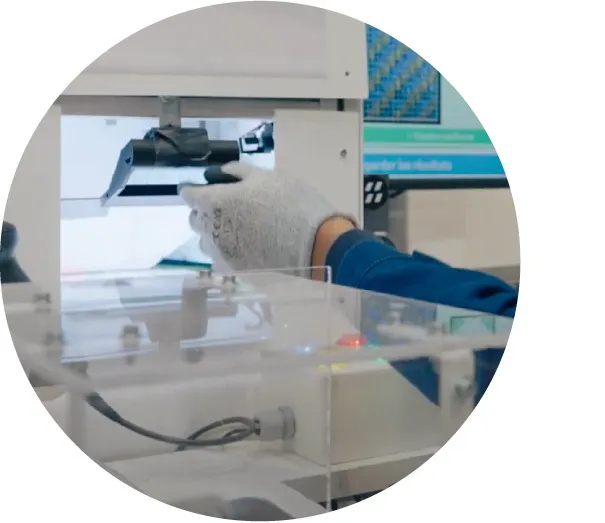

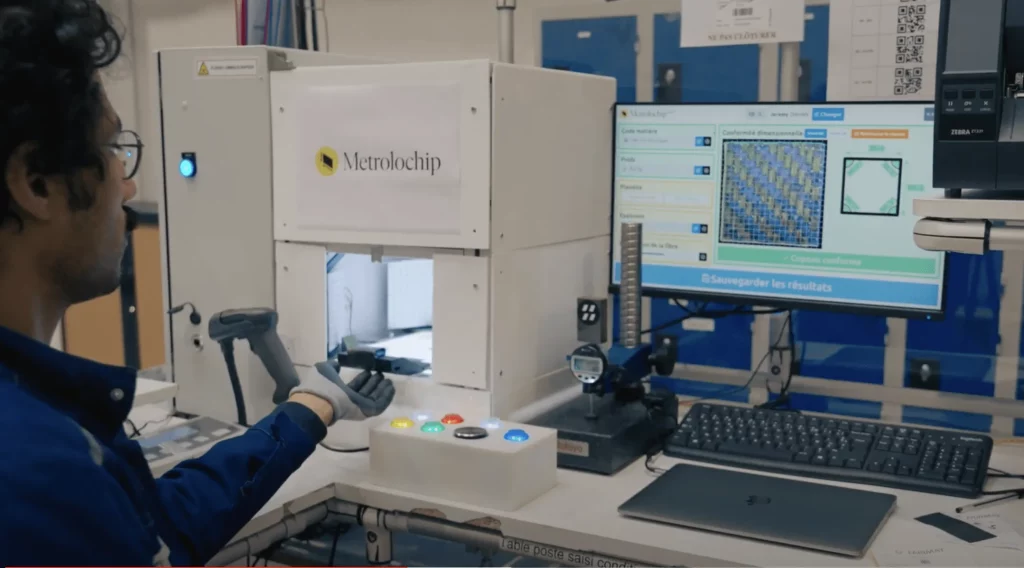

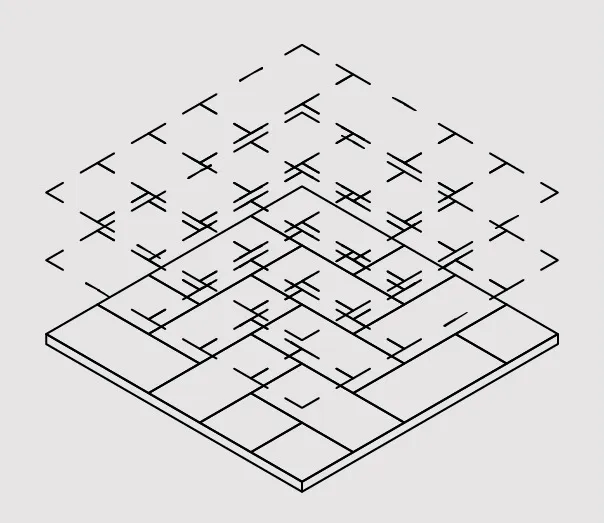

2. Processing

Produced chips are characterized using our bespoke “metrolochip” system, which uses advanced algorithms to perform optical analysis of our chips. We perform statistical sampling from every batch of chips to ensure the quality and consistency of processed chips.

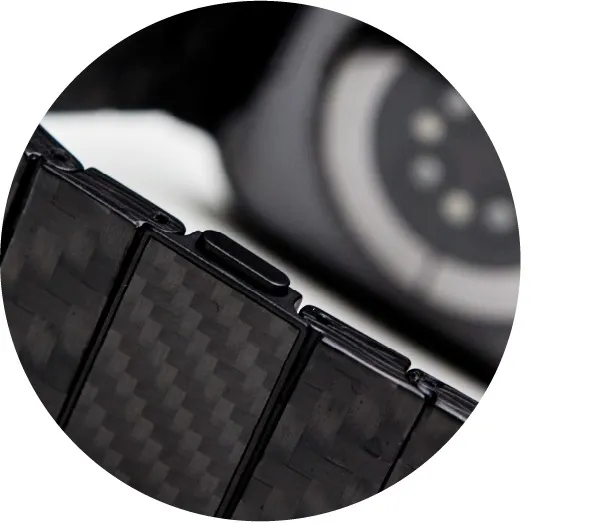

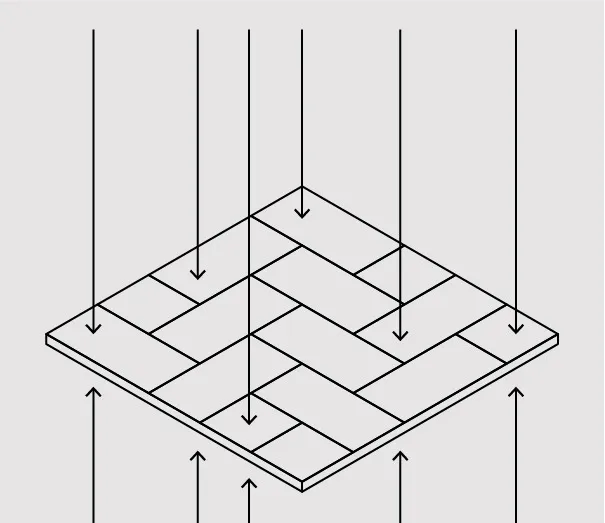

3. Production

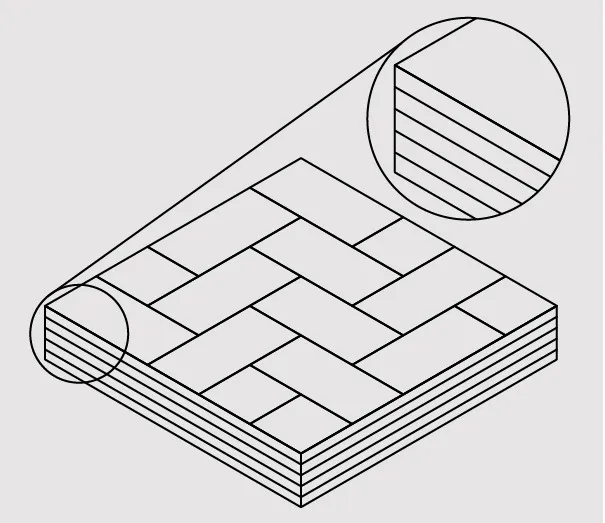

In the manufacturing phase, we use our tracked data to combine appropriate materials and ensure that the final composites, laminates, and parts meet all specified requirements.

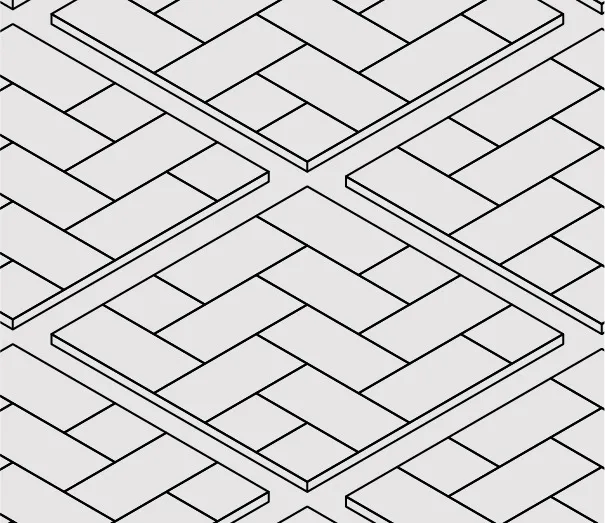

4. Final Inspection

Before delivery, each product undergoes a full QA/QC process to verify its quality and performance.

Quality Control Tests

To guarantee the highest quality and performance of our recycled materials, we conduct a series of rigorous tests at various stages of our process:

Incoming Material Analysis

Optical Inspection: Identifying any visible defects or contaminants in the reclaimed CFRP waste.

Chemical Analysis: Verifying the chemical makeup of the incoming materials to ensure they meet our specifications.

Mechanical Processing Tests

Optical Characterization: Characterizing the size, orientation, weaving, and uniformity of the mechanically processed rCFRP Chips.

Density Measurement: Performing helium pycnometry, the highest performance density measurement available, to verify the properties of our Chips.

Intermediate Product Testing

Tensile and flexural strength testing: Measuring the tensile and flexural strength to ensure our products will withstand the demanding mechanical forces in client applications.

Impact testing: Performing impact testing to ensure our products will withstand the most demanding physical shocks.

Final Product QA

Differential Scanning Calorimetry: Ensuring the consistency of our curing cycle.

Impact Testing: Determining the material’s ability to absorb energy and resist impacts.

Fatigue Testing: Assessing the durability and performance of the material under repeated loading conditions.

Scratch Resistance: Assessing the durability and resistance to scratching to ensure a long-lasting aesthetic finish.

Environmental Resistance: Assessing the durability under heat, moisture, sunlight, or other conditions appropriate to the product.

Final Inspection

Each product goes through an exhaustive inspection to ensure it conforms to all client specifications, including aesthetic surface quality, dimensional accuracy, and planrity.