DPS Skis x Fairmat: Pioneering the Next Generation of High-Performance, Durable Skis

DPS Skis, a leader in high-performance carbon fiber ski design, partnered with Fairmat to create skis that combine cutting-edge performance with sustainability. Together, they’re redefining what’s possible in winter sports.

THE CHALLENGE:

Maintain Cutting edge performance: DPS is the uncontested leader in carbon fiber ski design, having pioneered the successful implementation of these materials in an industry dominated by metals and fiberglass. Any new solution cannot come at a cost to the stiffness or liveliness of this lightweight ski.

Improve Sustainability without Drawbacks: High-performance skis require advanced materials, but traditional carbon fiber production has a significant environmental impact.DPS already uses sustainable resin systems but finding a sustainable source of carbon fiber that maintains performance had been impossible to date.

Durability Demands: Skiers push their gear to withstand extreme loads and conditions. A sustainable solution cannot jeopardize the structural integrity and durability of the product which are intended to perform season after season.

Circularity in Action: The ski industry needs a solution to address the growing issue of composite waste. An ideal scenario would be to ensure that some or all materials in a ski could be reused upon end of life without compromising build quality..

THE SOLUTION:

Fairmat’s recycled carbon fiber materials provided DPS Skis with the perfect balance of performance, durability, and sustainability:

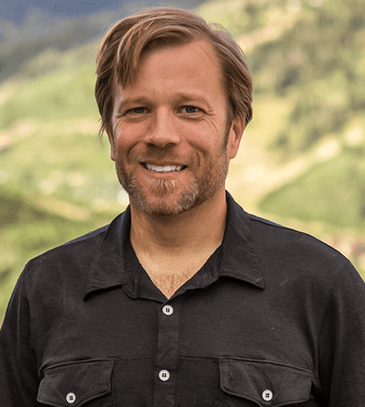

High Performance: Fairmat material is being used directly under the boot where the power is tranferred form teh skier to the ski, through teh binding. Engineering this traditionally neglected section of the ski created a design that met the demands of top athletes, including professional skier Ted Ligety, a two-time Olympic gold medalist.

Cost Efficiency: Fairmat technology enabled a direct 5% reduction in material costs compared to traditional solutions, making sustainability an economically viable choice

THE RESULTS:

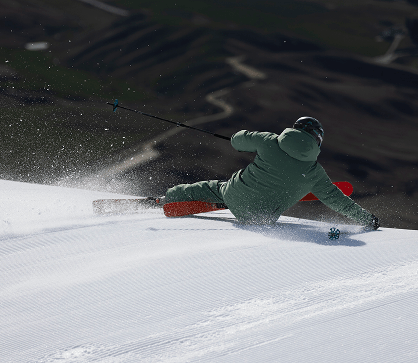

Launch of Pisteworks® Skis: DPS Skis introduced a new line of skis featuring Fairmat’s materials, setting a new standard for high-performance, eco-friendly winter sports equipment.

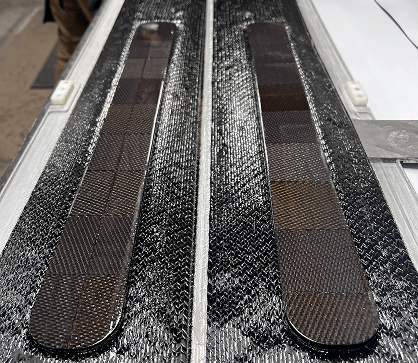

Enhanced Manufacturing: Fairmat components allow for an easier assembly of the different layers that come together to make a pair of skis. Not only is the material more cost effective than virgin materials, it enables significant savings by simplifying the operations and increasing productivity.

Enhanced Performance: The skis deliver superior power transmission by using high performance materials in areas traditionally neglected. An unforeseen benefit was the enhanced damping created by the semi-discontinuous nature of our materials. These improvements came at no detriment to durability, standing up to the abuse of the most demanding professional skiers.

Sustainability Milestone: A significant reduction in the carbon footprint of ski production was achieved not only by using recycled carbon fiber but also by reducing the amount of epoxy needed to impregnate and laminate different layers that make up a ski. By using precured chips, we can save over 50% of the resin required. This is aligned with DPS Skis’ commitment to protecting the planet

The new Pisteworks® skis in action on the slopes.

Behind-the-scenes shots of the manufacturing process, showcasing Fairmat’s materials being integrated into the skis.

Ted Ligety testing the skis in New Zealand.