Fairmat Sets A New Standard in Carbon Composites

FairPly’s plug-and-play design fits seamlessly into your existing processes, mixing easily with both virgin or recycled materials like glass fiber, carbon fiber, foams, and honeycombs. There’s no redesigns or bill of material changes needed. FairPly matches the price of the materials it replaces.

Try FairPly today and gain a sustainable edge on your product innovation, making an impact on both your business and the planet.

Elevate your products with FairPly – where cutting-edge technology meets sustainability

Engineered from Fairmat’s innovative recycled CFRP Chips, FairPly delivers an exceptional combination of sustainability and performance, without a green premium.

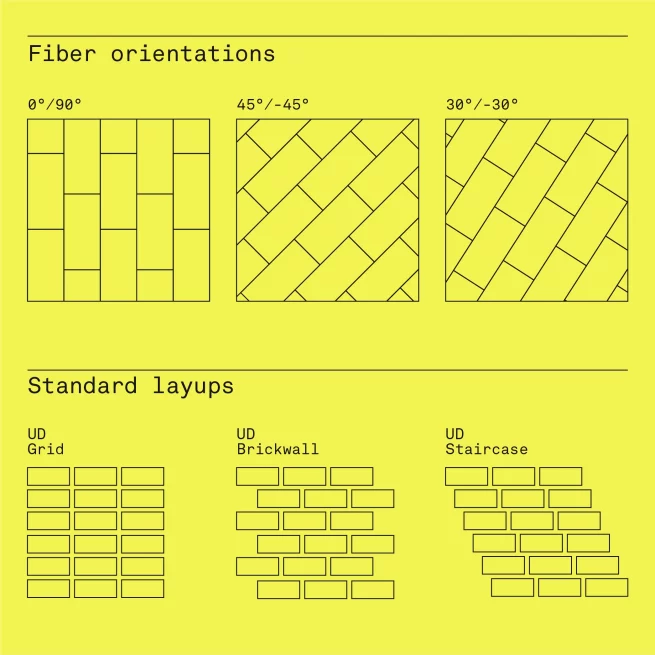

Customizability

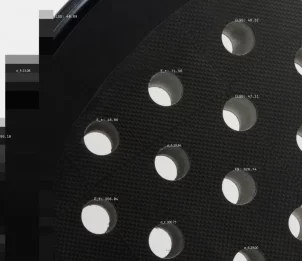

Customers can easily cut FairPly to shape and customize their layups to achieve the properties they desire. A variety of fiber orientations and standard layup configurations are available, offering flexibility to meet specific requirements. To ensure optimal performance, it’s important to offset Chip placement between layers, preventing alignment discontinuities.

Key characteristics and benefits

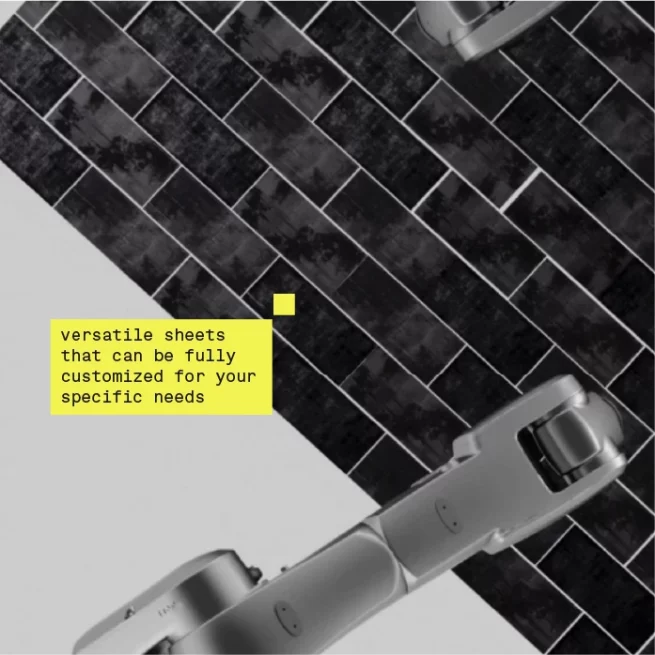

Engineered from Fairmat’s innovative recycled CFRP Chips, FairPly delivers an exceptional combination of sustainability and performance. These chips are expertly bonded to a substrate, creating versatile sheets that can be fully customized for your specific needs.

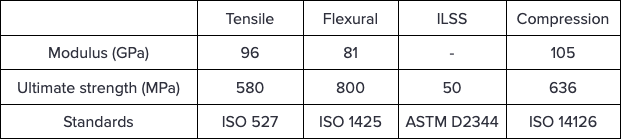

Product characteristics

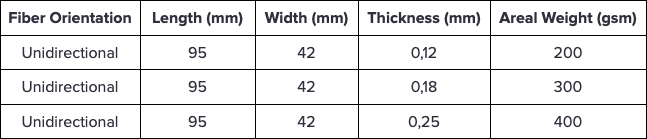

Recycled CFRP Chip characteristics

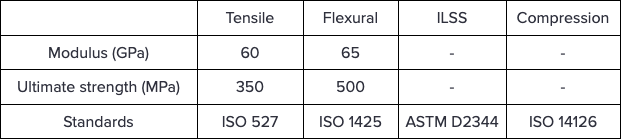

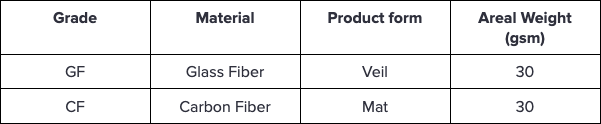

Substrates characteristics

FairPly Characteristics

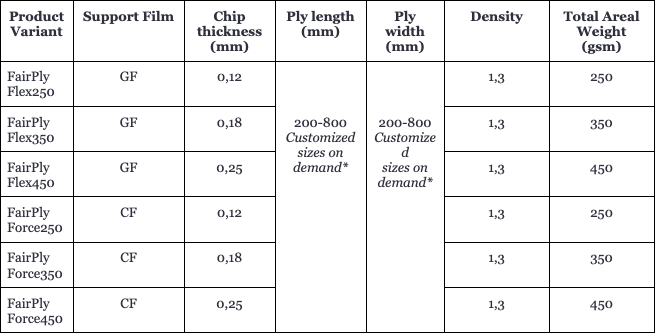

*For bigger Ply dimensions, please contact our sales support

FairPly Characteristics *For bigger Ply dimensions, please contact our sales support

GF: Glass Fiber veil

CF: Carbon Fiber mat

Contact us for samples

*Required Field

Fairmat Technology

Available as both prepreg and dry fabric, FairPly is perfect for a variety of industries—offering unmatched performance while reducing environmental impact.